Introduction:

At Minghang Glass, Glass bottle manufacturing involves a series of intricate processes that transform raw materials into the final product. This article outlines the step-by-step process involved in the production of glass bottles.

1、Raw Material Preparation:

The manufacturing process begins with the collection of raw materials such as silica sand, soda ash, limestone, and cullet (recycled glass).

These raw materials are carefully measured and mixed in precise proportions to create the glass batch.

2、Melting:

The glass batch is fed into a furnace where it undergoes high-temperature melting, typically ranging from 1400°C to 1600°C.

In the furnace, the raw materials fuse together to form molten glass, which is then homogenized to ensure uniform composition.

3、Annealing:

Once formed, the glass bottles pass through an annealing lehr, which is a long oven with a carefully controlled temperature gradient.

Annealing relieves internal stresses in the glass, making the bottles more durable and resistant to breakage.

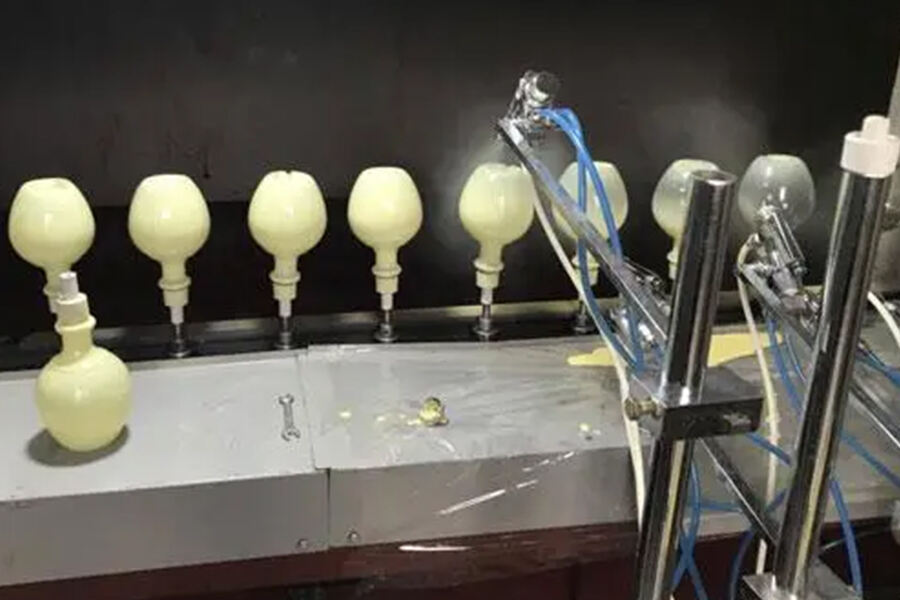

4、Surface Treatment:

After annealing, the bottles may undergo surface treatment processes such as coating, labeling, or printing.Coating processes may include spraying or dipping the bottles in materials to enhance their appearance or provide specific functionalities, such as UV protection or chemical resistance.

5、Inspection:

Quality control is an essential aspect of glass bottle manufacturing. Automated inspection systems are used to detect defects such as cracks, bubbles, or uneven thickness.

Any defective bottles are removed from the production line to ensure only high-quality products reach the market.

6、Packaging:

Once inspected and approved, the glass bottles are packaged according to customer specifications.

Packaging may involve placing the bottles in cartons, crates, or pallets for safe transportation to distribution centers or end-users.

Conclusion:

The production of Minghang glass bottles involves a meticulously orchestrated series of steps, from raw material preparation to packaging. By adhering to strict quality control standards, manufacturers ensure that the final product meets the requirements of customers and consumers alike.

EN

EN AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI HU

HU TH

TH TR

TR FA

FA GA

GA LA

LA MI

MI MN

MN